Diamond Tools: Precision Results Guaranteed

Cutting, grinding, drilling: anyone aiming for precision reaches for diamond tools. They cut harder, last longer, and work more efficiently — diamond tools have long been indispensable in crafts and industry. The gold standard becomes the diamond standard. But what makes these tools so special?

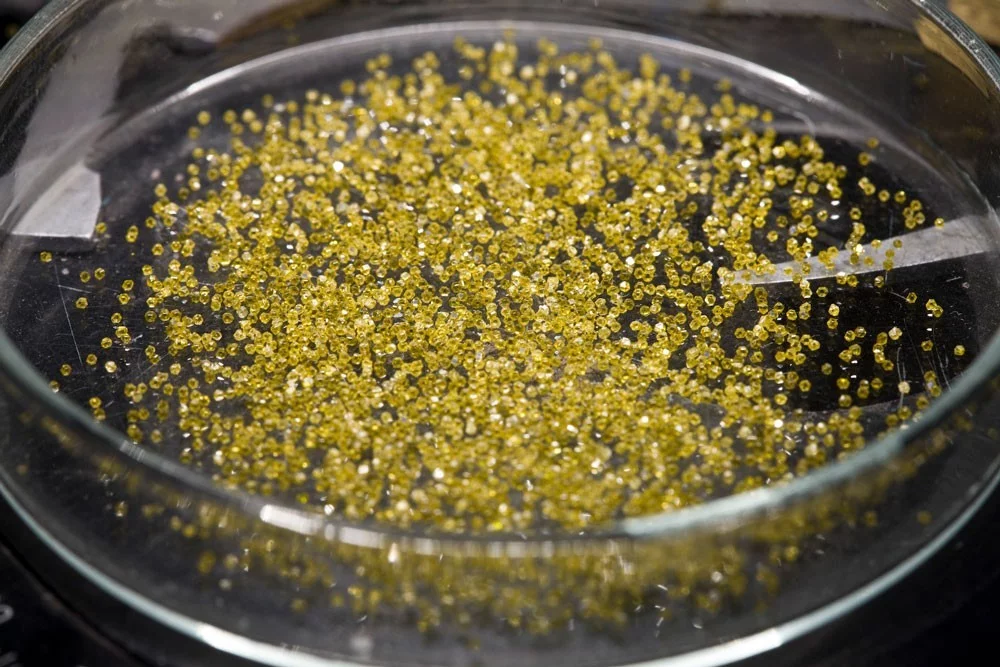

Take a diamond cutting disc in your hand. The base of each disc is the core blade: a robust metal body with segments embedded with industrial diamonds. These diamonds make the difference. Especially the synthetic high-performance diamonds used by DIEWE set new benchmarks: five times more resistant than natural diamonds, sustainably produced, precisely dosed.

They are manufactured under extreme pressure and heat — over 1,500 °C and 60,000 bar. The result is pure cutting power in crystalline form. A technology designed for durability, cutting performance, and sustainability. And thus delivers exactly what professionals expect.

Your work demands uncompromising results – and for that, you need uncompromising quality. That’s exactly what you can expect from DIEWE diamond cutting discs:

Comparison: Diamond Tools vs. Hammer Drills and Pneumatic Hammers

• Fewer tool changes, more flexibility

• High cutting speed for clean edges

• Long service life, even under heavy use

• Lower motor power needed, reduced wear

• Cooling effect for consistent cutting performance

• Noise-reducing hole patterns for more comfortable work

• Increased productivity with less downtime

• Custom adjustments depending on material and application

Comparison: Diamond Tools vs. Hammer Drills and Pneumatic Hammers

Whether in crafts, industry, or trade: without precise tools, there’s no precise result when working with masonry, tiles, or roof tiles. Hammer drills and pneumatic hammers are rough, loud, and high in vibration. Diamond tools are quieter, faster, more refined. Less force, dust, and noise—embrace the diamond standard now.

| Diamond Tool | Hammer Drill/Pneumatic Breaker | |

| Workload | Minimal physical strain | Considerable physical and psychological strain |

| Precision | Clean and dimensionally accurate work | Unclean breakout points due to fractures on surfaces and edges |

| Impact on Concrete Matrix and Reinforcement | Preservation of adjacent structures thanks to a vibration-free working method | Loosening of concrete matrix and reinforcement |

| Environment | Low noise and dust-free | Strong and persistent noise pollution and significant dust generation |

| Costs | Lower costs for closing the remaining cross-section | Increased costs for closing the remaining cross-section |

| Other Characteristics | Unhindered use of adjacent rooms possible without problems | Rapid performance decline with increasing working duration |