Diamond Tool Damaged or Dull?

Has the cutting performance of your diamond cutting blade dropped off? That doesn’t necessarily mean it’s broken—dull blades can be rejuvenated. Here’s how to restore them quickly and cost-effectively.

Why Your Cutting Blade Becomes Dull

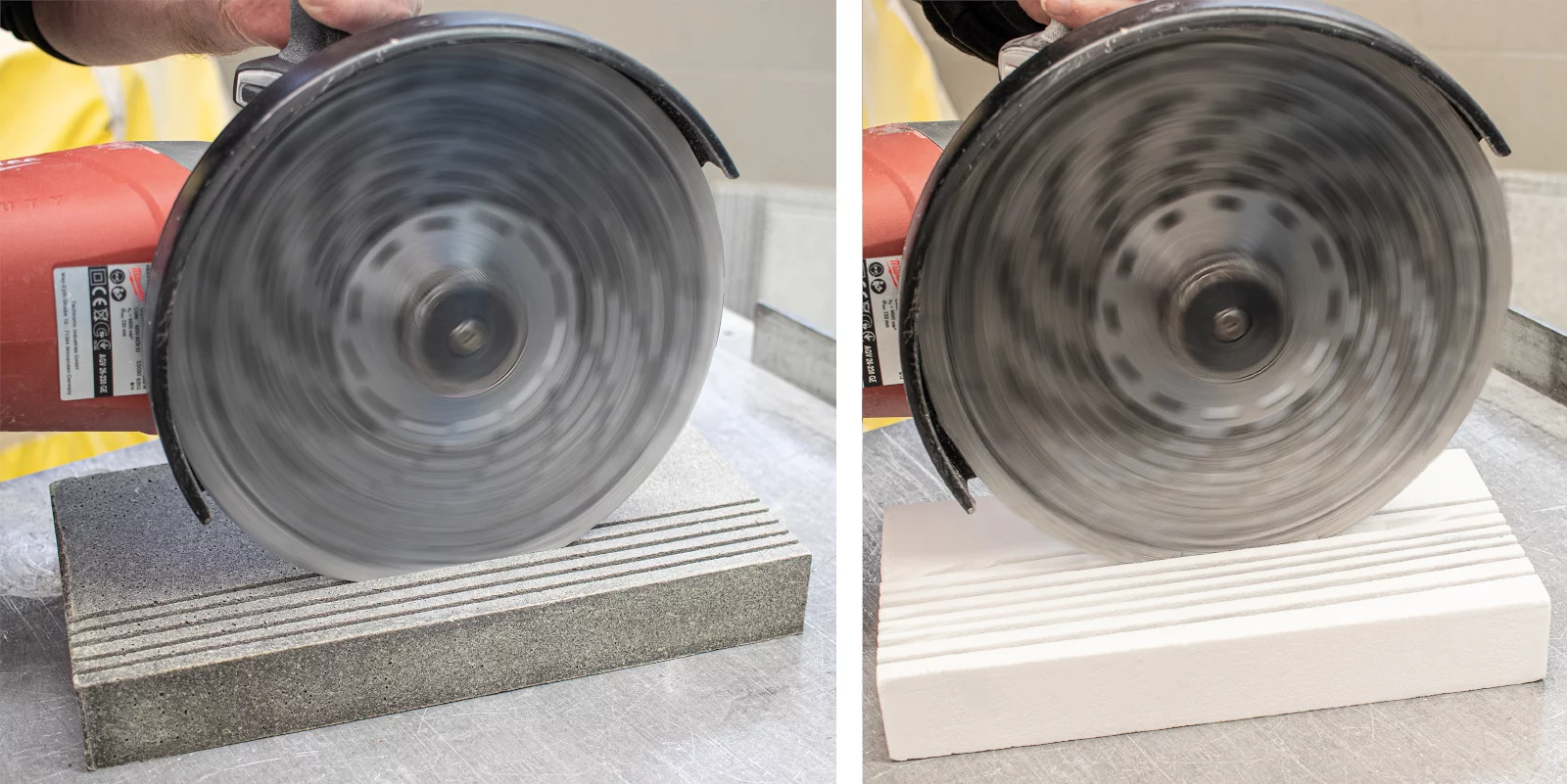

Extremely hard materials, continuous load, or applying too much pressure while cutting and drilling can all blunt diamond tools—this is normal wear. The good news: you can resharpen the rim of a dull blade with a dressing plate or dressing stone. DIEWE supplies the right products—and we’ll show you the steps.

Tip: Always resharpen dry!

Make several intense, shallow dressing cuts (no deeper than the segment height) until the gullets are no longer visible.

After a few passes, switch the machine off and let the blade coast down with light pressure on the dressing stone. Repeat this process several times.

The blade is fully sharpened when fresh, sharp-edged diamonds with supporting tails are exposed, as shown in the illustration on the right.

Does the blade dull again after a short cutting time? Then switch to blades with a softer bond. If you’re experiencing excessive wear, blades with a harder bond are more suitable—even if that means the cutting progress is slightly slower.